Excellent product qualities with high productivity

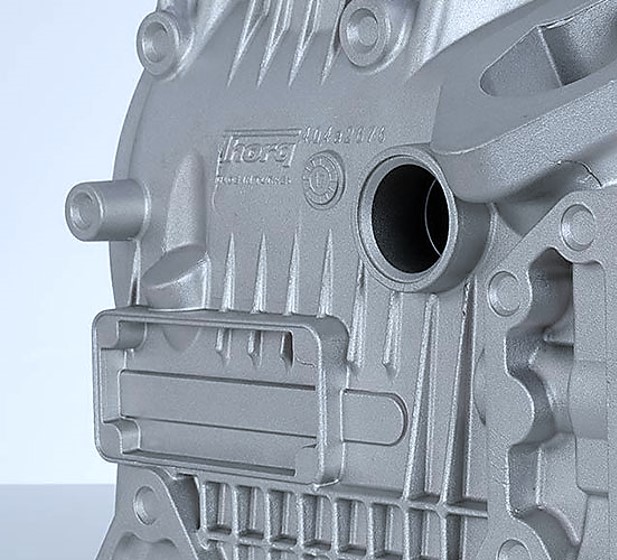

TERRA offers innovative solutions for demolding processes in die casting and injection molding applications made with light alloys such as aluminium, magnesium, titanium, zinc and copper.

Derivated from the functional Silicone Fluid and Silicone Resin mixtures, TERRASIL® serie Silicone Emulsion for Release provide easy demolsing while providing target qualities in the final product in terms of surface quality and technical features.

TERRASIL® serie release agents increase efficiency, reduce energy and labor costs, minimize rate of waste, and contribute to the Sustainability without compromising cost-effectiveness.

For further information about our solutions for Light Alloy & Aluminium Die Casting, please contact us. Our experts will assist you in making the right choices to secure the product properties you seek.

PRODUCT RECOMMENDATIONS

> TERRASIL® RSN 1040 MQ

Methyl MQ Silicone Resin (Trimethylsiloxysilicate)

Pure white powder silicone resin with 100% active content. It is well suited tor the formulation of surface care, car care, and plastic and and rubber care products. It is also used in the release agent formulations used for injection molding and die-casting. The product has excellent water-resistant film-forming performance. It can be compounded with polydimethylsiloxanes or dissolved in appropriate solvents like aromatic and non-aromatic hydrocarbons or lower alcohols. The solubility is excellent.

> TERRASIL® RSN 1060 MQ

Methyl MQ Silicone Resin (Trimethylsiloxysilicate)

Pure white powder silicone resin with 100% active content. It is well suited tor the formulation of surface care, car care, and plastic and and rubber care products. It is also used in the release agent formulations used for injection molding and die-casting. The product has excellent water-resistant film-forming performance. It can be compounded with polydimethylsiloxanes or dissolved in appropriate solvents like aromatic and non-aromatic hydrocarbons or lower alcohols. The solubility is excellent.

> TERRASIL® RSN 1600 MQ

Silicone MQ Resin (Alkylsilicone Resin)

Pure white powder silicone resin. It can be compounded with polydimethylsiloxanes or dissolved in appropriate solvents like aromatic and non-aromatic hydrocarbons or lower alcohols. The solubility is excellent.

> TERRASIL® RA 5050

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® RA 5055

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® OPE 2144

Functional Silicone Emulsion

As lubricant and release agent for molding and extrusion. As textile enhancer for fabric finishing for denim, as elastomeric coating for polyester fiber (PES) yarn and glass fiber, as additive for paints and surface coatings to impart elasticity, high mechanical strength, friction resistance and high heat resistance.

> TERRASIL® OPE 5065

Functional Silicone Emulsion

As lubricant and release agent for molding and extrusion. As textile enhancer for fabric finishing for denim, as elastomeric coating for polyester fiber (PES) yarn and glass fiber, as additive for paints and surface coatings to impart elasticity, high mechanical strength, friction resistance and high heat resistance.

> WACKER® TN

Functional Silicone Fluid

Modified silicone fluid of medium viscosity whose special chemical structure imbues it with the benefits of silicone fluids and mineral oils. is used for the formulation of release agents for thermal molding of rubber, plastics and low-melting nonferrous metals. It is superior to conventional silicone fluids when the finished parts are subsequently to be painted, printed, coated or bonded.

> WACKER® TNE 50

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

APPLICATIONS

> Automotive Parts

> Furniture Parts

> Armature

> Electrical and Electronic Parts & Equipments

> Lighting Equipments

> Construction Equipments

> Building Elements

> Aviation, Space and Defense Industries Equipments

> Connection Elements & Valves

> Hand Tools

> Kitchenware

> Machinery and Equipment

> Textile Accessories

> Die Casting

> Aluminum Die Casting

> Aluminum Injection Molding

> Aluminum Compression Molding

> High Pressure Die Casting (HPDC)

> Pressure Die Casting

> Light Alloy Die Casting

> Aluminum Pressure Die Casting

> Aluminum Alloy Die Casting