Innovative silicone technologies for electrical and eletronics industries

We offer a broad range of silicone based raw materials, additives and process aids for electrics, electronics and lighting.

SILASTOSIL® EP serie liquid silicone rubbers (RTV-2) for electronic potting and encapsulation, SILASTOSIL® LR serie liquid silicone rubbers (LSR) for injection molding, TERRAFLUID® serie phenyl and methyl silicone fluids for electrical insulation and thermal conductivity, and other process aids we offer support to readily obtain all technical features in electrical parts and electronic system components.

Our flexible solutions provide users unlimited application flexiblity with high comfort of use, assure smooth-running processes, and increase productivity while optimizin costs. They are well suited to achieve all performance criteria in terms of electrical insulation or conductivity, thermal management and service life. They can meet every requirement in accordance with IEC, UL 94 and ISO.

We help you stay competitive

Cooperating with well-known global solution providers in electrical and electronic industries, we offer the most innovative silicone rubber technologies which guarantee long-term competitiveness:

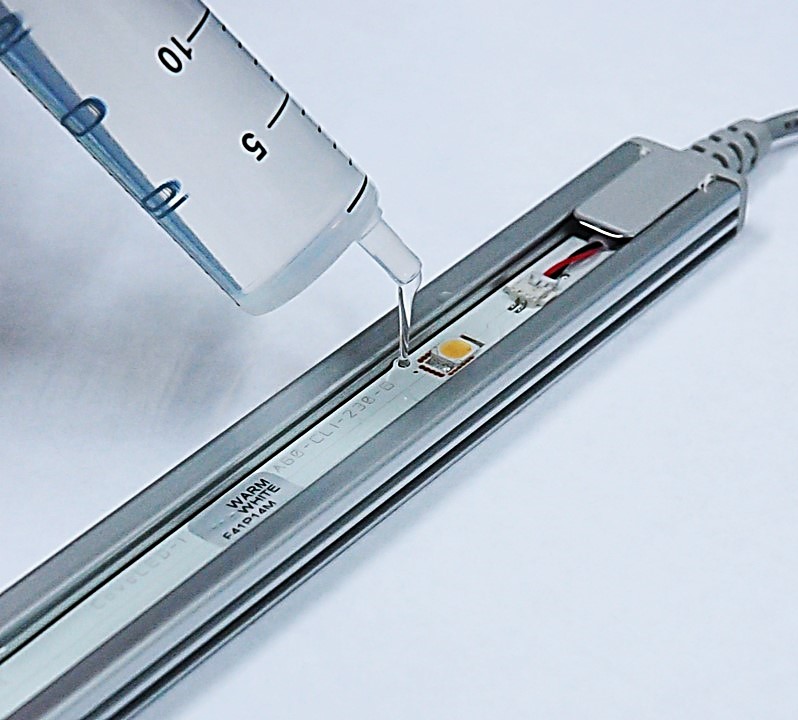

> RTV-2 Silicone Rubber for Electronic Potting and Encapsulation

> Silicone Rubbers & Additives

> Silica

For further information about our solutions used in Electrics, Electronics & Lighting, please contact us. Our experts will assist you in making the right choices to secure the product properties you seek.

PRODUCT RECOMMENDATIONS

> SILASTOSIL® EP 2115 A/B

Room-Temperature-Vulcanizing Silicone Rubber (RTV-2)

Pourable, condensation-curing two-component (100:5) liquid silicone rubber for electronic potting and encapsulation. Clear transparent, colourless.

Hardness 10-15 Shore A.

> SILASTOSIL® EP 2115 A/B BLACK

Room-Temperature-Vulcanizing Silicone Rubber (RTV-2)

Pourable, condensation-curing two-component (100:5) liquid silicone rubber for electronic potting and encapsulation. In black color.

Hardness 10-15 Shore A.

> SILASTOSIL® EP 2210 A/B

Room-Temperature-Vulcanizing Silicone Rubber (RTV-2)

Pourable, condensation-curing two-component (10:1) liquid silicone rubber for electronic potting and encapsulation. Clear transparent, colourless.

Hardness 15 Shore A.

> SILASTOSIL® EP 2215 A/B

Room-Temperature-Vulcanizing Silicone Rubber (RTV-2)

Pourable, condensation-curing two-component (10:1) liquid silicone rubber for electronic potting and encapsulation. Black colour.

Hardness 15-20 Shore A.

> SILASTOSIL® EP 2220 A/B

Room-Temperature-Vulcanizing Silicone Rubber (RTV-2)

Pourable, condensation-curing two-component (10:1) liquid silicone rubber for electronic potting and encapsulation. Clear transparent, colourless.

Hardness 15-20 Shore A.

> SILASTOSIL® EP 2650 A/B

Room-Temperature-Vulcanizing Silicone Rubber (RTV-2)

Pourable, addition-curing two-component (1:1) liquid silicone rubber for electronic potting and encapsulation. Gray colour.

Hardness 50-55 Shore A.

> SILASTOSIL® LR 3030 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 27 to 33 Shore A.

> SILASTOSIL® LR 3040 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow shore hardness range from 37 to 43 Shore A.

> SILASTOSIL® LR 3045 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow shore hardness range from 42 to 48 Shore A.

> SILASTOSIL® LR 3050 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 47 to 53 Shore A.

> SILASTOSIL® LR 3060 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 57 to 63 Shore A.

> SILASTOSIL® LR 3065 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 62 to 68 Shore A.

> SILASTOSIL® LR 3070 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 67 to 73 Shore A.

> Holcosil® LR

Colorant

Liquid pigment paste for coloring RTV-2 and LSR liquid silicone rubbers, highly effective, easily dispersible. Food contact and skin contact, FDA confirmed.

> TERRASIL® PRIMER 6400

Primer & Adhesion Promoter

Additive used as primer and adhesion promoter for addition-curing RTV-2 and LSR liquid silicone rubbers.

> TERRACOAT® LR 2010 A/B

Liquid Silicone Rubber (LSR) for Textile Coating

Low-viscous flowable, easily-pigmentable two-component silicone rubber compound with short curing times. Ideal for cable sleeving and coating on technical textiles. Good penetration, strong adhesion, high elongation, excellent mechanical and chemical strenghts and electrical insulation. Clear transparent, colorless and odorless, reduced volatile content, non toxic and non hazardous, skin contact.

Narrow Shore hardness range from 10 to 12 Shore A.

> SILASTOSIL® HTV 9230

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 27-32 Shore A.

> SILASTOSIL® HTV 9240

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 37-42 Shore A.

> SILASTOSIL® HTV 9250

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 48-52 Shore A.

> SILASTOSIL® HTV 9260

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 60-65 Shore A.

> SILASTOSIL® HTV 9270

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 68-73 Shore A.

> SILASTOSIL® HTV 9280

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 78-82 Shore A.

> TERRAFLUID® MP 75

Methyl Phenyl Silicone Fluid

CAS No. 63148-58-3

Clear, colorless, and odorless polydimethylsiloxane with a high proportion of phenyl groups. Viscosity of approx. 75 mm²/s.

> TERRAFLUID® MP 100

Methyl Phenyl Silicone Fluid

CAS No. 63148-58-3

Clear, colorless, and odorless polydimethylsiloxane with a high proportion of phenyl groups. Viscosity of approx. 100 mm²/s.

> TERRAFLUID® MP 125

Methyl Phenyl Silicone Fluid

CAS No. 63148-58-3

Clear, colorless, and odorless polydimethylsiloxane with a high proportion of phenyl groups. Viscosity of approx. 125 mm²/s.

> TERRAFLUID® MP 150

Methyl Phenyl Silicone Fluid

CAS No. 63148-58-3

Clear, colorless, and odorless polydimethylsiloxane with a high proportion of phenyl groups. Viscosity of approx. 150 mm²/s.

> TERRAFLUID® MP 200

Methyl Phenyl Silicone Fluid

CAS No. 63148-58-3

Clear, colorless, and odorless polydimethylsiloxane with a high proportion of phenyl groups. Viscosity of approx. 200 mm²/s.

> TERRAFLUID® MP 500

Methyl Phenyl Silicone Fluid

CAS No. 63148-58-3

Clear, colorless, and odorless polydimethylsiloxane with a high proportion of phenyl groups. Viscosity of approx. 500 mm²/s.

> TERRAFLUID® MP 1000

Methyl Phenyl Silicone Fluid

CAS No. 63148-58-3

Clear, colorless, and odorless polydimethylsiloxane with a high proportion of phenyl groups. Viscosity of approx. 1000 mm²/s.

> TERRAFLUID® DM 10

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 10 mm²/s.

> TERRAFLUID® DM 20

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 20 mm²/s.

> TERRAFLUID® DM 50

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 50 mm²/s.

> TERRAFLUID® DM 100

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 100 mm²/s.

> TERRAFLUID® DM 350

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 350 mm²/s.

> TERRAFLUID® DM 1000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 1000 mm²/s.

> TERRAFLUID® DM 5000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 5000 mm²/s.

> TERRAFLUID® DM 12500

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 12500 mm²/s.

> TERRAFLUID® DM 60000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 60000 mm²/s.

> TERRAFLUID® DM 100000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 100000 mm²/s.

> TERRAFLUID® DM 300000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 300000 mm²/s.

> TERRAFLUID® DM 600000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 600000 mm²/s.

> TERRAFLUID® DM 1000000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 1000000 mm²/s.

> TERRASIL® RSN 1600 MQ

Alkylsilicone Resin (Silicone MQ Resin)

Pure white powder silicone resin. It can be compounded with polydimethylsiloxanes or dissolved in appropriate solvents like aromatic and non-aromatic hydrocarbons or lower alcohols. The solubility is excellent.

> TERRASIL® RSN 8000

Silicone Resin

A medium hard methyl phenyl silicone resin supplied as 82 wt.%-solution in xylene. Ideal for use as binder for heat-resistant anticorrosive paints and coatings.

> TERRASIL® RSN 6000

Silicone Resin

A medium hard methyl phenyl silicone resin supplied as 60 wt.%-solution in xylene. Ideal for use as binder for heat-resistant anticorrosive paints and coatings.

> TERRASIL® RSN 5000

Silicone Resin

A medium hard methyl phenyl silicone resin supplied as 50 wt.%-solution in xylene/n-butanol (9:1). Ideal for use as binder for heat-resistant anticorrosive paints and coatings.

> TERRASIL® 1100 SILICA

Hydrophobic Precipitated Silica

CAS No. 67762-90-7

> TERRASIL® 1300 SILICA

Hydrophobic Precipitated Silica

CAS No. 67762-90-7

> TERRASIL® 3200 SILICA

Hydrophobic Precipitated Silica

CAS No. 112926-00-8

> HDK® H15

Hydrophobic Pyrogenic Silica

CAS No. 68611-44-9

> HDK® H17

Hydrophobic Pyrogenic Silica

CAS No. 67762-90-7

> HDK® H18

Hydrophobic Pyrogenic Silica

CAS No. 67762-90-7

> HDK® N20

Hydrophilic Pyrogenic Silica

CAS No. 112945-52-5

APPLICATIONS

> Electrical & Electronics

> Lighting Components

> Photovoltaics

> Solar Energy Panel

> Electronic Potting & Encapsulation

> Electrical Insulation

> Electrical Conductivity

> Thermal Management

> Thermal Conductivity

> Thermal Insulation